Kitchen Fire Suppression System Technology Selection

Kitchen Fire Suppression System is of 2 types in terms of working principle. - Mechanical Systems and Pneumatic Systems

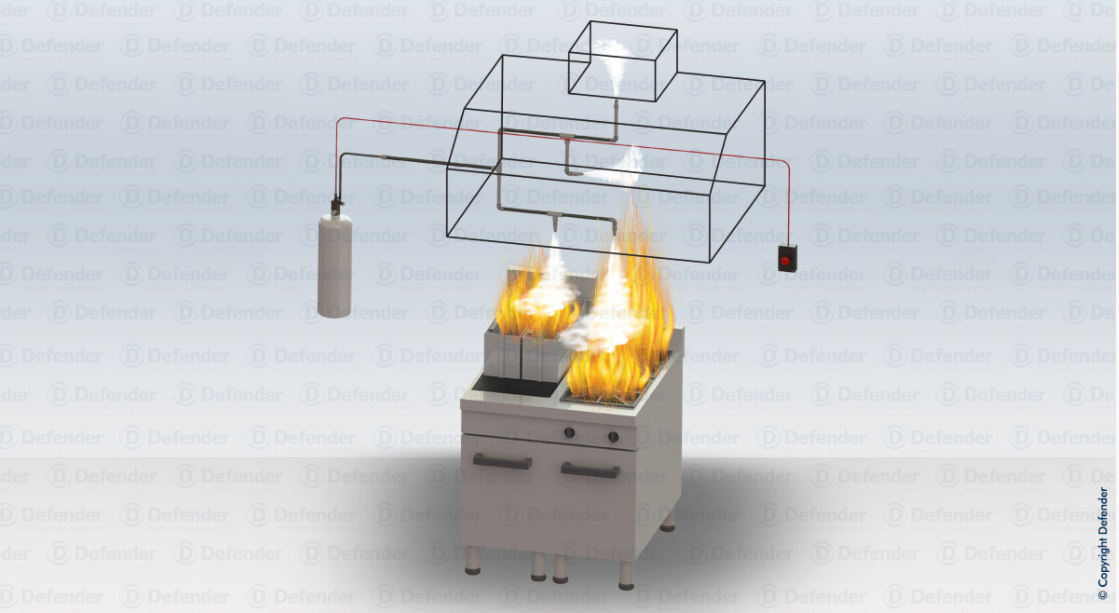

Mechanical Systems

Fusible or Thermo Bulb detectors are integrated into a spring loaded mechanism. By triggering the detectors at high temperatures, a valve is activated using the pressure of the propellant cartridge (CO2 or N2) in the system mechanism. The fire is extinguished by spraying the chemical extinguishing liquid in the pressurized tube through the discharge pipes and with nozzles.

The advantage of these systems is that they work according to mechanical rules and their components are metal and their high heat and corrosion resistance. They show high resistance to impact and adverse conditions. The disadvantage is that system setups are difficult and periodic maintenance costs are high.

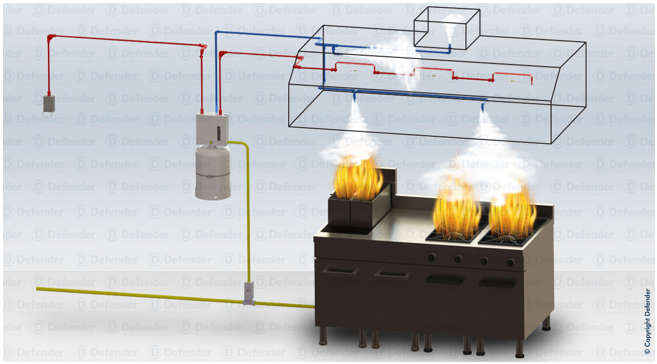

Pneumatic Systems

These systems operate by melting and explosion of pressurized detector hose in the face of temperature. A valve is activated when the gas pressure in the hose decreases. The fire is extinguished by spraying the chemical extinguishing liquid in the pressurized tube through the discharge pipes and with nozzles. The advantage of this type of systems is that the detector hose makes precise detection at many points inside the hood. The disadvantage is that the heat resistance of the detector hose cannot exceed 130 ° C. This type of hoses are made of PA (polyamide) material. PA materials, on the other hand, undergo structural deterioration after 90 ° C maximum. Although they are reinforced with additives, their structure is completely destroyed at a maximum temperature of 130 ° C.

For this reason, it is a disadvantage not to be used in hoods with high temperatures.